Inverted Box Rib IBR Roofing Sheets Rolling Machine

Professional Manufactuer of Steel & Aluminium Roll Forming Machine, Roll Former, Corrugating Machine, Rolling Plant, Rollformer from China

Aluzinc IBR Profiled Roof Cladding Sheet Rollformer Machine

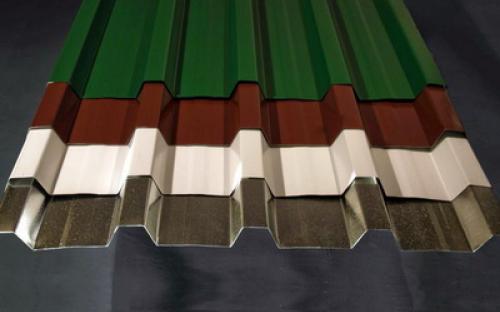

IBR (Inverted Box Rib), with an effective cover width of 686mm after a side-lap, is an angular trapezoidal fluted sheet designed for use as roof covering and side wall cladding or roofing material in commercial, industrial and residential buildings.

This aluzinc IBR profile roofing sheet making machine is an advanced metal roll former, which is manufacturing aluzinc IBR shaped roofing sheets and wall sheets with a high speed. This aluzinc IBR roof profiles roll forming machine consists of decoiler, sheet guiding equipment, rollforming system, cutter, support table, hydraulic system, and control system.

CHARACTER

It is really a new type of energy-saving and high-efficiency metal IBR roof sheets rollformer. And it has many advantages, just like high forming speed, low noise, stable transmission, easy operation, good appearance and so on.

MAIN PARAMETERS:

1. Material Thickness: 0.4mm to 0.7mm

Galvanised Steel Sheets in COILS (ex: JIS 93 302)

Prepainted Galvanized Steel Sheets in COILS (ex: JIS G 3312)

Galvalume Steel (ALUZINC) Simple or Prepainted in COILS

Aluminium Sheets in COILS (ex: AA 5005 & 3003)

2. Hydraulic decoiler Max. Capacity: 5000KGS

3. Controlling system: PLC

4. Main machine power: 4kw

Hydraulic station power: 2.2kw

5. Working speed: 18~20m/min

6. PLC: PLC control panel, transducer and touching screen imported from Mitsubishi

7. Power: 380V/3ph/50HZ or at buyer's requirement.

Low Machine Cost/High Machine Quality/Short Time for Recouping Investment

If you want to get more information about this aluzinc roofing panels roll former machine, such as price, delivery time, payment and so on, please contact us by the following information:

Email: [email protected]

Mobile: +0086 158 6814 2550

Place of Origin: China